附件3:C-0501AB制硫炉风机设备数据.xls

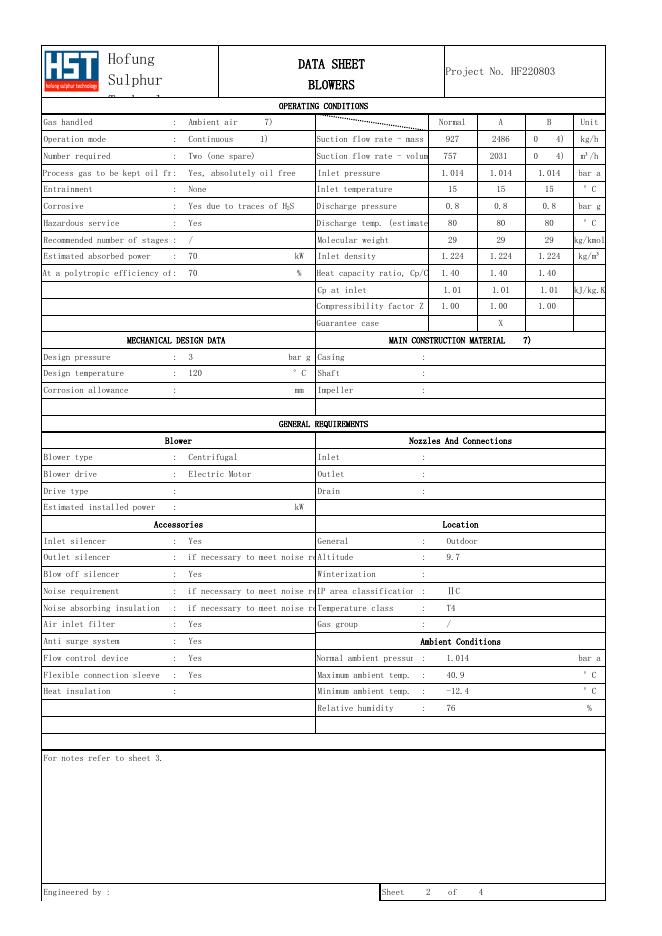

Hofung Sulphur Technology DATA SHEET Project No. H:F220803 BLOWERS Main Air Blower C-0501A/B 0 24/03/2023 For PDP Rev. Issue Data Revision Description Client : Jiangsu Sopo (Group) Co., Ltd Plant : Sulfur Recovery Unit Location : Zhenjiang, Jiangsu, P.R. China Equipment : Sheet Prepared Checked Approved Client by by by approval 1 of 4 Main Air Blower Equipment No. : C-0501A/B Data No. HF220803-P07.2-EDS-03 : Hofung Sulphur Technology DATA SHEET Project No. H:F220803 BLOWERS OPERATING CONDITIONS Gas handled : Ambient air 7) Normal A Operation mode : Continuous 1) Number required : Two (one spare) Suction flow rate - mass 927 2) 2486 0 4) kg/h Suction flow rate - volume 2) 757 2031 0 4) m³/h Process gas to be kept oil free : Yes, absolutely oil free Inlet pressure 1.014 1.014 1.014 bar a Entrainment : None Inlet temperature 15 15 15 °C Corrosive : Yes due to traces of H2S Discharge pressure 2)0.8 3) 0.8 0.8 bar g Hazardous service : Yes Discharge temp. (estimated) 80 80 80 °C Recommended number of stages : / Molecular weight 29 29 29 kg/kmol Estimated absorbed power : 70 kW Inlet density 1.224 1.224 1.224 kg/m³ At a polytropic efficiency of : 70 % Heat capacity ratio, Cp/Cv 1.40 1.40 1.40 Cp at inlet 1.01 1.01 1.01 Compressibility factor Z 1.00 1.00 1.00 Guarantee case MECHANICAL DESIGN DATA 5) 6) : 3 bar g Casing : Design temperature : 120 °C Shaft : Corrosion allowance : mm Impeller : Unit kJ/kg.K X MAIN CONSTRUCTION MATERIAL Design pressure B 7) GENERAL REQUIREMENTS Blower Nozzles And Connections Blower type : Centrifugal Inlet : Blower drive : Electric Motor Outlet : Drive type : Drain : Estimated installed power : kW Accessories Location Inlet silencer : Yes General : Outdoor Outlet silencer : if necessary to meet noise requ. Altitude : 9.7 Blow off silencer : Yes : Noise requirement : if necessary to meet noise requ. IP area classification : ⅡC Noise absorbing insulation : if necessary to meet noise requ. Temperature class : T4 Air inlet filter : Yes : / Anti surge system : Yes Flow control device : Yes Normal ambient pressure : 1.014 bar a Flexible connection sleeve : Yes Maximum ambient temp. : 40.9 °C Heat insulation : Minimum ambient temp. : -12.4 °C Relative humidity : 76 % 2 of Winterization Gas group Ambient Conditions For notes refer to sheet 3. Engineered by : Sheet 4 Hofung Sulphur Technology Equipment No. : C-0501A/B Data No. HF220803-P07.2-EDS-03 : NOTES : Hofung Sulphur Technology DATA SHEET Project No. H:F220803 BLOWERS 1) The blower shall be able to run continuously within the whole range of the specified cases: Normal : The operation of the blower at a normal throughput of the SRU train at average ambient conditions. Case A : Maximum flowrate, including an overcapacity for upsets, is the blower design capacity. Case B : Situation where the process unit is tripped while the blower remains in operation. 2) The specified discharge pressure and flow are the net required pressure and flow for the process at the battery limit of the blower man All pressure losses in the suction & discharge upto limits of his scope of supply and air blow-off for control purposes shall be added by the blower manufacturer. 3) An air blower performance curve is to be supplied for the blower. 4) In case of an automatic shut-down of the Sulfur Recovery Unit, the blower will remain in operation for an extended period, while the ai the process is stopped. The blower shall be safeguarded against overheating and / or surging. In case of automatic shut-down of the Sulfur Recovery Unit, the air valve (outside vendor's scope) closes within 5 seconds. The blower control shall be capable of handling this situation. 5) The air flowrate in kg/h is controlled by the process and is independent of the air intake temperature, ambient pressure and humidity. Air intake temperature = ambient temperature. 6) The blower efficiency is to be maximum for the normal operating conditions. 7) Ambient air may contain max. 25 ppm vol% H2S (for material selection only). No copper or copper alloys to be used in equipment. For additional material requirements see 'Material Specification' doc.no. : HF220803-P04-MLS. 8) Air blower shall be capable to: a) Start and operate against fully closed discharge valve to the downstream process (blower-unit to be equipped with blow-off valve). b) Operate over the full range from specified minimum flow up to and including specified maximum flow (where applicable, blow-off of ex via blow-off valve of blower-unit ). c) Provide air at a as much as possible constant pressure to the downstream process over the full range from specified minimum flow up including specified maximum flow. d) Keep running when discharge valve to downstream process is closed rapidly due to a trip of the process (blower control shall be fast to avoid a trip of the blower-unit). e) Operate in parallel with stand-by blower, and enable smooth transition from operation of one blower to stand-by blower, without dist operation of the downstream process. 9) Typical drawing is for reference only, vendor to design anti surge system. 10) The combustion air blower discharge pressure is to be automatically controlled, depending on the selected blower configuration, via blo atmosphere (preferred), inlet guide vanes, VSDS or other. Engineered by : Sheet 3 of 4 Hofung Sulphur Technology Equipment No. : C-0501A/B Data No. HF220803-P07.2-EDS-03 : Hofung Sulphur Technology DATA SHEET Project No. H:F220803 BLOWERS TYPICAL (NOTE 1) Notes : 1) Final blower selection and anti-surge requirements to be determined by vendor and approved by detailed contractor/client. 2) Winterizing requirements for air intake and filter to be determined by vendor. Engineered by : Sheet 4 of 4 Hofung Sulphur Technology Equipment No. : C-0501A/B Data No. HF220803-P07.2-EDS-03 :

附件3:C-0501AB制硫炉风机设备数据.xls

附件3:C-0501AB制硫炉风机设备数据.xls